·Plastic coloring requirements

For product color design, generally have the following requirements:

1, for users, the appeal of the United States have the power

2, in line with the purpose of the product, use, function;

3, suitable for the use of the environment color;

4, eliminate unnecessary decoration;

5, consider the color of production prices;

6, consider the suitable production engineering, processing technology color;

7, consider the relationship with the competition of goods, there is the effect of trafficking in the display color;

8, suitable for consumer hobbies, fresh, popular keen colors.

·The expected effect of plastic coloring

The effect of plastic coloring is expected to include the following:

1, to provide decorative effect of commodity value;

2, literacy color that effect;

3, to protect the deterioration of content to prevent the deterioration effect (anti-UV);

4, hide the contents;

5, improve the plastic weather resistance;

6, to improve the optical properties of the diffusion effect;

7, thermal attraction, thermal reaction;

8, to promote plant growth.

·Colorant

Now there are thousands of types of plastic colorants can be divided into pigments, dyes, and pigments can be divided into organic pigments, inorganic pigments. Inorganic pigments are mainly titanium dioxide, carbon black and molybdenum, chromium, cadmium, iron and other metal oxides. Many kinds of dyes, mostly from coal tar (Coal tar) derivatives such as indanthrone (Indenthrene) class, azo, nitro, phthalocyanine (Phthalocyanine) class. In general, organic pigments and dyes, bright colors, color strength, but heat, ultraviolet light is very weak. Inorganic pigments are vivid, color strength is small, but heat, ultraviolet light fastness good.

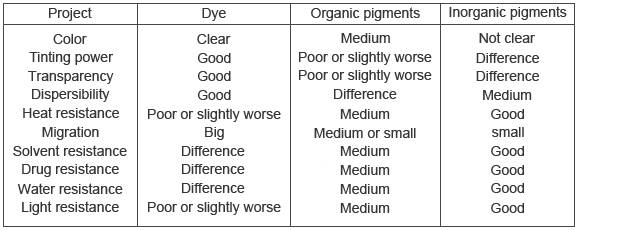

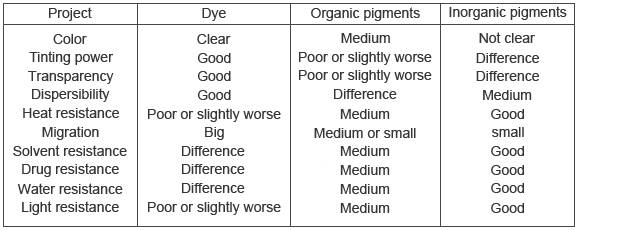

Pigments in the plastic is a state of solid particles to disperse, while the dye is dissolved in the plastic, the molecular form of staining. Dyes are usually soluble in plastic matrix, transparent dispersion, the pigment was insoluble and opaque. Dye was dissolved state, not only rich hue, bright colors, and excellent dispersion, but there are migration (Migration) or bleed (Bleeding) and other shortcomings. Pigments do not have this problem, but the transparency is poor. General color with organic pigments, and white black brown with inorganic pigments. The following table compares the properties of various colorants:

For different uses of plastic products, the use of pigments have different requirements, such as outdoor use must have good weather resistance, optical rotation, the hot springs region required to have good resistance to sulfur, children's toys and food packaging products must be no Toxicity, transparency for agriculture or packaging, opacity for shading, and the like.

When a pigment is used in a plastic article, the following basic conditions must generally exist:

1, Vividness, Tinting power, concealing power;

2, excellent dispersion;

3, heat resistance;

4, weather resistance;

5, resistance to migration;

6, good compatibility and will not affect the product properties;

7, water resistance, solvent resistance, chemical resistance;

8, resistance to sulfur;

9, electric color insulation;

10, environmental protection.